Sturdy, high-quality finishing products that feature the latest in precision-based optical engineering

We understand that a one-size-fits-all approach to eyewear manufacturing doesn’t cut it. For over 25 years, we’ve listened to the needs of our customers—designing cutting-edge finishing solutions that have helped countless laboratories profitably adapt to the changing optical landscape.

An innovator in the optical industry, we were the first manufacturer to tailor our edge blocks to various lens shapes and styles—ensuring each lens is protected from scratches, crazing and breakage during the edging process.

From digital gauges with millimeter-scale accuracy, to automatic deblockers that process hundreds of parts per hour, our finishing products improve lens quality and performance, increase throughput and save you costs.

We make our finishing products from high-quality materials and incorporate the latest in precision-based optical engineering.

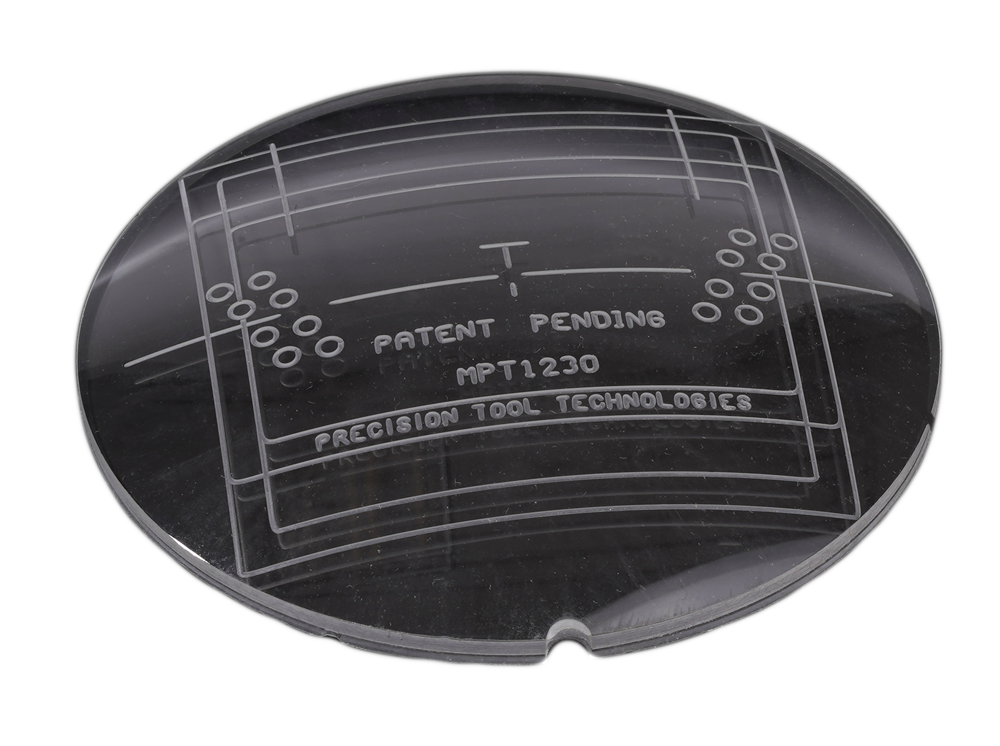

Edge Blocks

Our edge blocks feature our design fit technology—providing even pressure on lenses and achieving the perfect fit. We offer a wide range of edge blocks In Weco and LOH styles, ensuring lenses of various shapes, sizes and styles are secured during the edging process. By reducing lens scratches and crazing, these parts play a pivotal role in minimizing your finish room breakage. Our edge blocks—such as our Deep Drive, Super Flex, Versi-Edge and Perfect Wrap series—conform to any base curve. They’re also available in oval configurations and come in full-eye and half-eye sizes.

Automation Job Trays

No matter the equipment you have in your laboratory, we can configure our Versi Tray series to fit your needs. Choose from ten color options and two tray heights—2.75 inches (standard) and 3.25 inches for larger frames. An optional clear lid protects frames from polish and slurry, while lens pillow inserts repel liquids, prevent lens scratches and stop lenses from moving in automated systems. We also offer sturdy mobile racks to transport your job trays from station to station. Check out all the available optional features in our catalog.

View Our CatalogFinishing Gauges

Our durable finishing gauges help you transform uncut lenses into complete eye wear with the correct refractive power. Awarded an Optical Labs Association (OLA) Award of Excellence, our digital Digi-Sizer II gauge precisely measures existing lenses and patterns on blocked and unblocked lenses—producing fast, accurate and repeatable readings to 0.1 millimeters.

View Our CatalogQC2 Lens

QC2 = quality control and quick check. Our QC2 Lens provides a fast, accurate solution for your entire finishing process. Available with polycarbonate or CR-39 lenses, the QC2 features an engraved grid—allowing you to check the size and edger axis in half the time.

View Our CatalogChucks

Featuring our design fit technology, our chucks—together with our edging blocks and backside followers—ensure snug, even pressure on lenses during the edging process. We offer chucks for many different types of edgers and blockers.

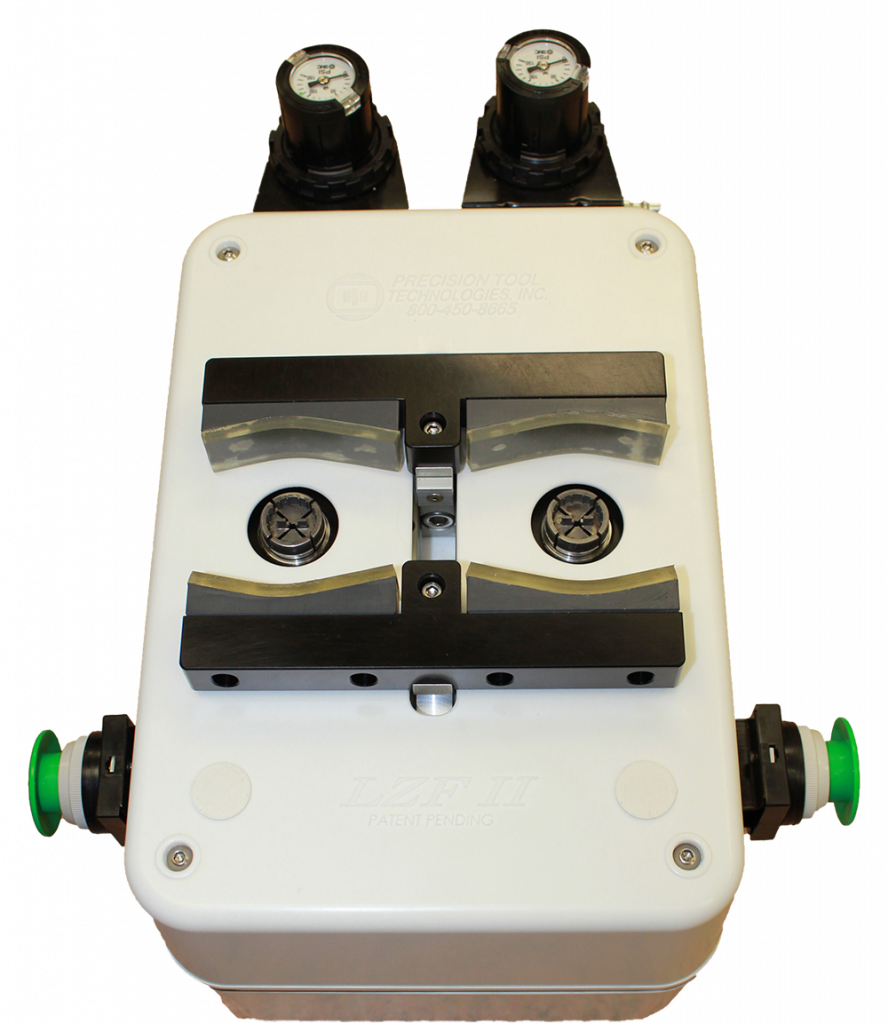

View Our CatalogDeblockers

Our deblockers effectively protect lenses from scratches and crazing—minimizing breakage during the finishing processes. Our automatic deblocking options, like our LZFII-1-AUTO-EZ and LZFII-1 deblockers, safeguard workers from repetitive wrist movements. They also accommodate whole-eye, half-eye and oval edge blocks and can process up to 250 parts per hour—improving your overall workflow.

We also offer handheld deblocking pliers. Made from scratch-resistant plastic, these cost-effective options feature a sleek, ergonomic design that reduces operator fatigue.

Lens Etching Kits

With our Lens Etching Mask Kit, you can easily mark the lenses of your prescription safety eyewear with your company’s initials. Markings meet ANSI safety eyewear standards. A simple, cost-effective solution, the kit lets you change from one mask to another to meet different safety standards.

View Our CatalogService

Rapid prototyping. Send us your file, and we’ll quote any part that can fit in our build area and generate an affordable prototype.

Precision balancing. We’ll check and balance your tooling and tool holders—improving cutting performance, process reliability and machine life.

Let’s Talk About Your Struggles

Contact us today to learn more about how our finishing products can benefit your lens manufacturing process.