We bring advanced machining resources to every project

Take one look at our high-end CNC equipment, deep machining expertise and proprietary automated production systems, you will quickly see that we're a machine shop like no other. And we combine our manufacturing capabilities with best-of-class support for your supply chain management requirements.

Capabilities and Equipment

Best of The Best

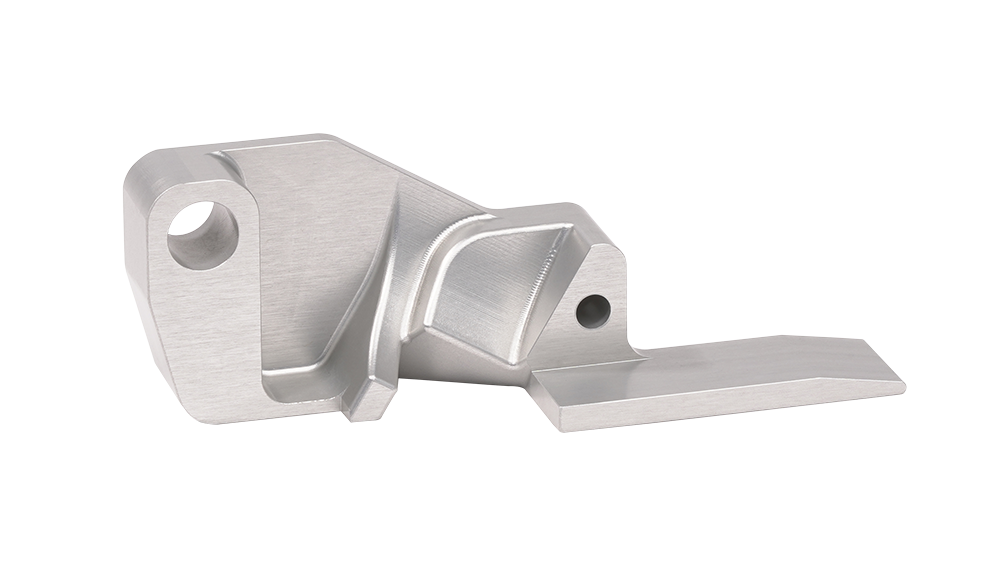

While we run all the five-axis CNC machines, turning centers and EDM systems you would expect from an advanced manufacturing operation, the jewels of our shop are our Willemin-Macodel five-axis-plus machining centers.

The Willemin-Macodel machines exemplify our commitment to manufacturing the most difficult parts with maximum automation and efficiency. Running bar stock and tended by robotic handlers, these highly-automated CNC machines have the ability to machine the front and back of most parts simultaneously—reducing setups and cost for even the most challenging parts. That capability means we can deliver your most complex, contoured parts quickly and cost effectively.

Key Equipment

- Willemin-Macodel machining centers

- Electrical discharge machines (EDM)

- DMG MORI—lathe/milling machines

- Miyano Citizen—lathes with simultaneous independent machining

- Robotics and automation technology

- Multi-axis equipment

- Tool room machines

- See the complete equipment and facility list →

Certifications

At Precision Tool Technologies, we are often asked “What tolerances can you hold?” The honest answer is “it depends”. Since there are a number of factors that can influence process capability on a given

part, feel free to contact us directly if you have specific questions about our ability to conform to tolerances on your project.

Please use the technical data below as a guideline only.

Machining

Our customer’s drawings typically require +/-.005″

unless otherwise specified, however it’s not uncommon for us to see +/-.0005″ for key

characteristics and critical dimensions.

Turning

Precision Tool Technologies, on a wide range of materials

routinely holds turned tolerances to +/-.0003″ and occasionally less than this.

Milling

Our capabilities include holding milled positional tolerances to +/-.0005″ and occasionally less than 0.0005″ on both position tolerances and Datum related features.

EDM

Hole size: +/-.0003″ or possibly better

Locations: +/-.0003″ or possibly better

Multi-Tasking/Multi-Axis Machining

| Type | Max Diameter | Length |

|---|---|---|

| Mill-Turn | 3.15″ | 27.7″ |

| 5-Axis Mill-Turn | 2.56″ | 9.8″ |

Lathes

| Type | Max Diameter | Length |

|---|---|---|

| Chucking | 10.8″ | 27.7″ |

| Tool Room | 8.0″ | 24″ |

| Gang Tool | 4.0″ | 99″ |

Vertical Mills

| # of Axes | X Travel | Y Travel | Z Travel |

|---|---|---|---|

| 4 | 33″ | 19″ | 17″ |

| 3 | 30″ | 16″ | 28″ |

Rapid Prototyping

| Type | X Travel | Y Travel | Z Travel |

|---|---|---|---|

| FDM | 16″ | 14″ | 16″ |

EDM

| Type | X Travel | Y Travel | Z Travel |

|---|---|---|---|

| Wire | 16″ | 12″ | 8″ |

| Sink | 12″ | 10″ | 10″ |

Surface Grinding

| Type | Rated Capacity | Wheel Diameter |

|---|---|---|

| Precision | 6″ x 12″ | 8.75″ |

At Precision Tool Technologies we work with a wide range of materials ranging from common aluminum and carbon steels to more exotic alloys. We use a wide range of raw materials suppliers to cost effectively source material. In most cases, Precision Tool Technologies manages procurement of all raw materials, helping our customers simplify their supply chain.

| Type | Grades/Specification/Brand/Type/Group |

|---|---|

| Aluminum | All structural grades including aerospace and marine types including 6061, 6061-T6, 7075 |

| Carbon Steel | All grades including Damascus |

| Plastics | All machinable grades including PEEK, Acrylic, Ultem |

| Stainless Steel | Ferritic, Martensitic, Precipitation Hardening and Duplex including 303, 316, 304, 17-4, 416, 420, 402 |

| Magnesium | Cast/Wrought |

| Titanium | Grades 3, 4, 5, 6 |

| Nickel | Kovar, Hastelloy, Invar, Inconel, Monel |

| Tungsten | MT-185 |

| Copper | Including brass, bronze |

| Molybdenum | Machinable grades |

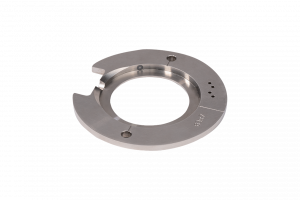

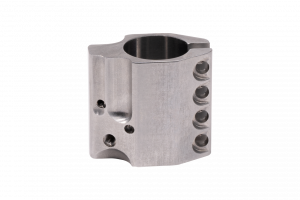

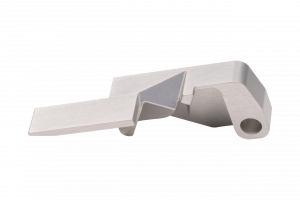

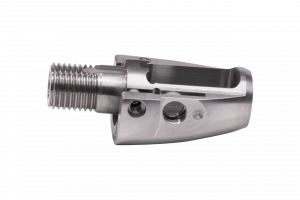

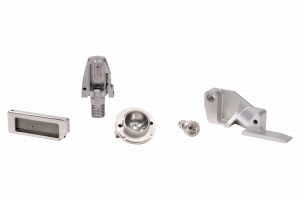

Application Examples

A Commitment to Automation

Our extensive use of advanced CNC controls, robotics and an proprietary automated coolant delivery system allow us to run our machines unattended overnight. This lights-out operation changes the economics of machining, allowing us to be both fast and cost competitive and helping you meet your time-to-market and profitability goals.

Learn MoreWe Like Challenges

Get in touch if you have difficult-to-make parts that other shops just cannot seem to get right. We specialize in parts that require challenging dimensional and surface finish requirements, complex contours, multiple operations or all of the above. And if you need a vanilla CNC part, we can do that too—only faster.

Get Started

Ready for Your Supply Chain

We ship plenty of low-volume and quick-turn jobs, but we also have a long record of working with customers with more complex supply chain needs. We routinely work under blanket orders and are agile enough to keep pace with changing forecasts and orders.