Your design-to-manufacture resource for precision injection-molded parts

From quick medium-volume jobs to high-volume recurring production runs, our injection molding operation has been designed from the ground up to be efficient, clean and quality conscious—all while guaranteeing the highest levels of accuracy, repeatability and predictability. We run only electric molding machines with integrated parts handling robots, creating a true lights-out manufacturing environment that minimizes costs and quality issues. And we offer design-for-manufacturability support to make sure your parts not only meets their functional requirements but also mold efficiently.

Capabilities and Equipment

Our Technical Advantages

Injection Molding Capabilities

- Clean manufacturing environment with all-electric equipment ensures optimal conditions for high-quality plastic injection molding.

- “Lights-out” capabilities save days to weeks of manufacturing time and keep costs low.

- Robotic pick-and-place systems increase production rates and maximize efficiency.

- Expertise with a wide variety of difficult-to-mold engineering thermoplastics.

- Cavity balancing to ensure part-to-part consistency in multi-cavity tooling.

- Insert overmolding.

- Secondary operations, including in-house laser marking and pad printing.

- Coordinate measurement machines (CMM) validate as-molded quality.

- An expert staff maintains and repairs tools, and makes adjustments and modifications to achieve accurate, repeatable results.

Key Equipment

- An all-electric lineup of Toshiba Electric Molding Machines, covering a wide range of clamp forces and shot sizes.

- Robotic handling systems for fast, hands-off parts removal and handling.

- Advanced auxiliary systems to ensure consistent material and molding conditions from pellet to part.

- See the complete equipment and facility list →

Certifications

| Model | Shot Size | Tons |

|---|---|---|

| Toshiba Electric EC310V30 | 37 oz. | 310 |

| Toshiba Electric EC200SXIIV50 | 15.41 oz. | 200 |

| Toshiba Electric ECN110V21 | 4.2 oz. | 110 |

| Toshiba Electric E85V30 | 3.3 oz. | 85 |

- Solidworks

- Gibbs

- Esprit

- Polyworks

- MFiles

- FEA and Stress Analysis

- Insert Molding

- Decorating

- Labeling

- Engraving

- Welding

- Balancing

- Post Run Automation

- Distribution

- Pad Printing

- Assembly

- Packaging

PTT injection molds a wide variety of engineering thermoplastics and elastomers, including:

- Acrylonitrile Butadiene Styrene (ABS)

- Polycarbonate (PC)

- ABS/PC Blends

- Nylons

- High Impact Polystyrene (HIPS)

- Thermoplastic Urethane (TPU)

- Acetal, such as Delrin®

- Polyvinyl Chloride (PVC)

- Thermoplastic Elastomers (TPE), including Santoprene® TPV

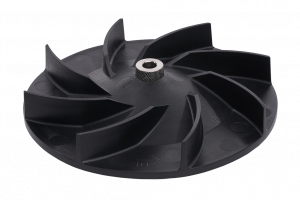

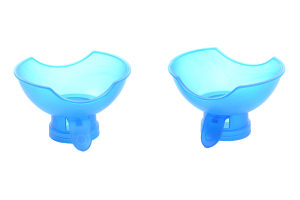

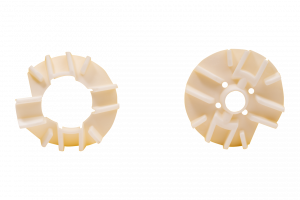

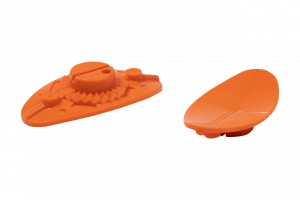

Application Examples

Let’s Talk About Your Struggles

Our injection molding capabilities can help you bring your products to market faster. To learn more about how we can meet your unique application needs, contact us today.