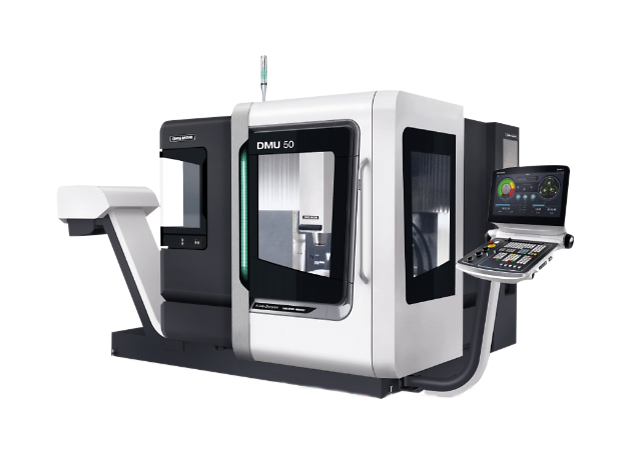

One of our core beliefs here at Precision Tool Technologies is that the future is bright for American manufacturers who invest in the right technologies. We recently made just such an investment with the purchase of a DMU 50 5-axis milling machine from DMG Mori.

It’s a great machine, with a built-in swivel rotary table that allows it to precision machine up to five axes simultaneously. The machine is capable of accuracies to 38 µin/in. It can machine parts up to 17.7 inches high and weighing up to 661 pounds. Its 20,000 rpm spindle speeds and rapid traverse capabilities give the machine a productivity edge over just about every other comparable machine tool we evaluated.

- Made for lights out. Even better than its impressive specs, the DMU 50 is a natural fit for our 168 Philosophy of unattended automation of machining operations. It supports a tool changer and pallet handling system, and its design also allows for easy robotics integration. And finally, we have the machine hooked up to our FullShop™ coolant automation system. Taken together, these features give us the ability to run the DMU 50 overnight with no operator needed, which dramatically improves our cost structure compared to more hands-on machining operations.

- 5-axis and automation go hand in hand. One reason we made the move to 5-axis machines is the desire to bring new efficiency to our ability to produce our customers’ most complex parts. But 5-axis machining also has an intrinsic advantage in lights-out scenarios—because they can machine parts in one pass that would require multiple, manual setups on a 3-axis machine.

Our investment in the DMU 50 goes beyond the machine itself. We’ve brought on a new engineer just to focus on this machine, helping our customers fine-tune part designs and manufacturing requirements to achieve the most efficient, capable and cost-effective machining processes.

You can learn more about our machining capabilities at www.precisiontooltech.com.