In our last post, we looked at the injection molding and manufacturing capabilities needed to produce a complex insert-molded part for use in an agricultural seed spreader. This glass-filled nylon part posed many manufacturability challenges, but the question we get the most is: How do you make sure these parts are truly balanced when they come out of the mold?

It’s a good question. The part has a demanding balance specification of 2.5 g-mm when spun at 12,000 rpm. And there’s a lot that can go wrong during the molding process that can can affect the ability to mold a perfectly balanced part — everything from the location of the insert in the tool to variations in materials, injection parameters and thermal conditions.

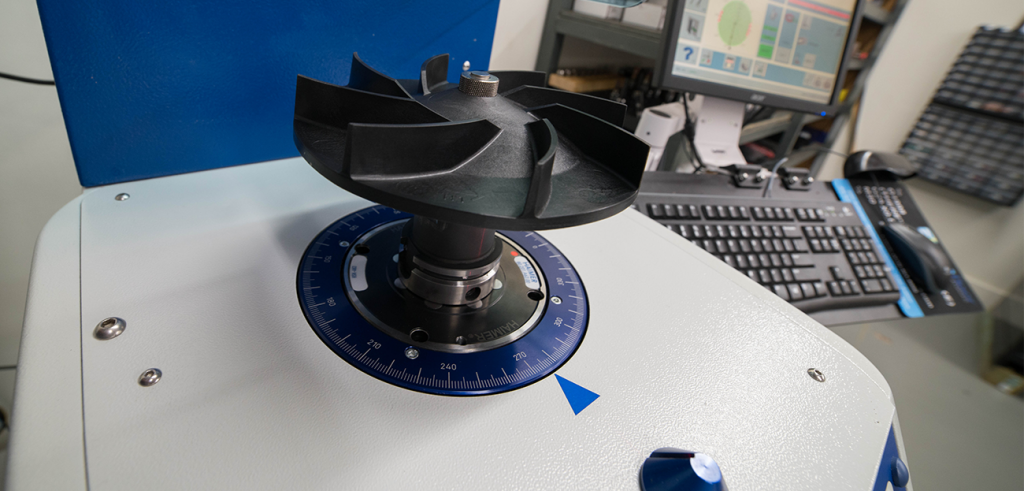

To make sure the molded parts meet the balance specifications, we turned to our Haimer tool balancer. We originally embraced tool balancing to support the production of precision optical laboratory tools. These optical tools required us to machine mold inserts and other components to exacting surface finish and dimensional tolerances — to 4 Ra and 0.0001 inch, respectively. And we found that balancing our CNC tooling assemblies made a big difference in hitting these very small tolerances consistently.

With the seed spreader, we built on our history with tool balancing, modifying the Haimer machine to spin the insert-molded part. The balancing machine makes it easy to run a test program and document the results. The machine can also laser mark any unbalanced regions of the part, which allowed us to develop a trueing process for parts that didn’t pass the test right out of the mold. With a test system in place and the ability to rework unbalanced parts, our yields for this job are close to 100%.

We’ve also put other fast-spinning parts on our Haimer machine, and believe we’ll do even more in the future. There are many insert-molded plastic and CNC metal components that need to meet a challenging balance specification.

To give us a whirl on a balanced part job, contact our engineering team.

Start The Quoting Process