Quality control in the optical lab is often challenging to identify, measure and correct. Edging calibration can be time consuming and labor intensive. Calibration tools don’t always reflect a laboratory’s actual finishing procedures. Optical labs need a simple way to bring all the disparate tasks together to create a structured, consistent quality control system for the finishing process.

For example, when it comes to validating a prescription, multiple process checks are needed just to analyze tracing, layout, drilling and edging axis. Using separate lenses to perform these tasks requires additional labor and time. Until recently, managers of finishing labs had to accept these inefficiencies. However, a newly developed lens system aims to unify finishing tasks to improve quality control.

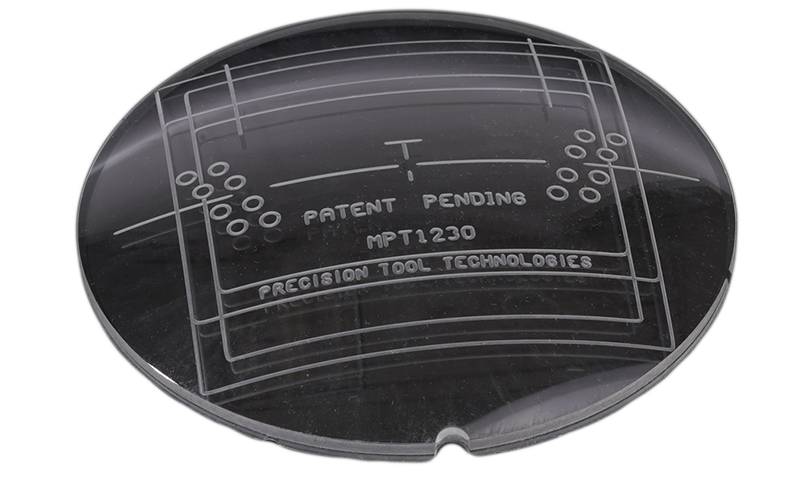

Precision Tool Technologies’ QC2 Calibration Lens is a fast, accurate calibration tool that uses a daily calibration method to show and isolate errors across the entire finishing process. The QC2 lens is designed to see quality visually and is simple to use. Having a template precision-machined on the lens allows lab personnel to easily see if the machines follow the machined pattern. Changes are required if the drilled holes didn’t hit the bullseye and edged shape is not parallel and square to the machined template on the QC2 lens.

- Tracing. QC2 lets users simulate a frame shape and process it as a normal prescription (Rx) via PTT’s Truform 2.5 Standard. This process is recommended for the first Rx of the day.

- Layout. Validate the layout axis and geometric position before edging.

- Edging. QC2 Lens features an engraved grid pattern to check edger axes and identify errors fast.

- Drilling. Check drill hole size and location during layout verification.

- Five-Axis Edging. Check shelving verification and position, in addition to size, axis and drilling.

QC2 lens solves common finishing issues such as crooked bifocals, off-axis shapes, wrong bifocal position, seg heights, slip-twist lenses, PD shifts, first time fit and more. The result: a structured daily process to ensure accuracy and consistency that also makes auditing easier. And when you use QC2 Lens with PTT’s other tools — Truform 2.5 Standard for tracing, Digi-Sizer II Digital Circumference Gauge with fast accurate readings to 0.1 millimeters, Alignment Gauge and Drilled Rimless Gauges — you’ll harmonize your processes to achieve a complete and efficient quality control system that will save your finishing lab both time and money.

Greater Structure, Efficiency and Productivity for Your Lab

Today, optical lab managers and opticians can use QC2 to identify lab edging issues, pinpoint the problem and verify if the problem has been solved. The QC2 Calibration Lens today is being used by many labs. Please consider QC2 Lenses in your lab today. The product is available in Poly and CR39.

For more information about Precision Tool Technologies’ QC2 Calibration Lens, view our catalog.