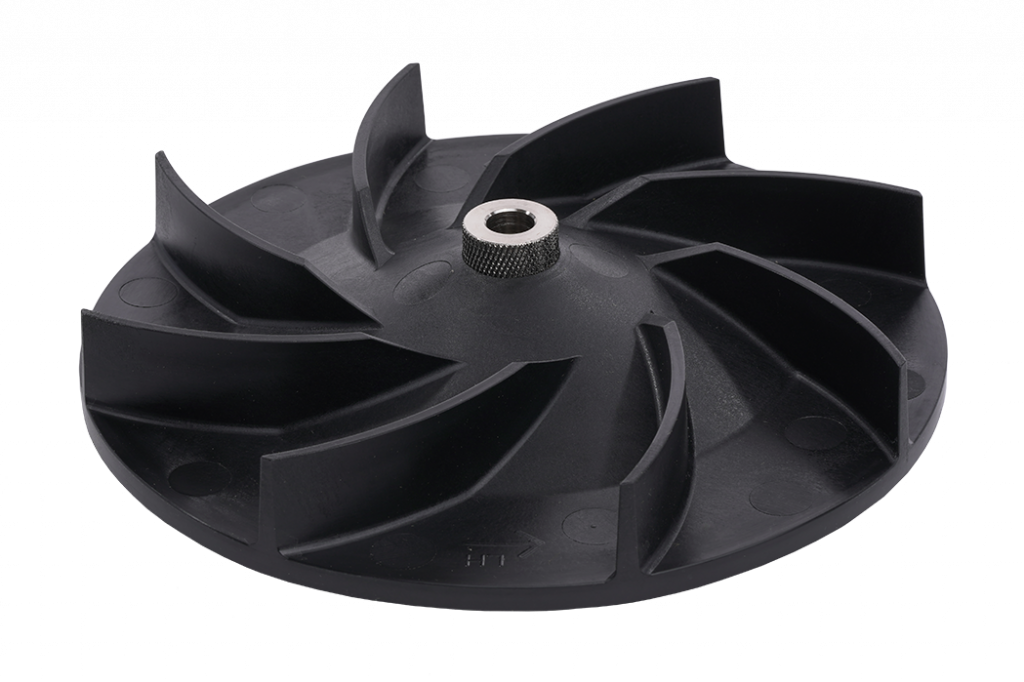

Sometimes the ability to just injection mold a part isn’t enough, and you really need a molder capable of a multi-disciplinary approach to manufacturing. That’s the case with a complex insert molded part we make for an agricultural seed spreader.

Not only does the part have challenging molding requirements, but it also requires us to precision machine a custom-designed metallic insert and qualify each part through functional testing. Here’s how we make it:

Mold it right. This insert molding job consists of two mirrored parts used in a seed spreader and aspirator — left- and right-spin versions that are otherwise identical. Molded from 30% glass-filled nylon, the part has demanding dimensional tolerances under ±0.002-inches that are all the more difficult to hold due to the part’s thick-to-thin wall thickness transitions.

Even more difficult were the challenges posed by the part’s key functional requirement — that it spin true at 12,000 rpm. That requirement forced us to pay extra attention to the molding process and tooling. In particular, we had to fine-tune the injection system to ensure that the plastic would fill the tool uniformly, leaving no locally heavy sections that would throw off the balance.

Stay Balanced. The other issue that would have affected the finished part’s balance is the location of the steel insert. After molding and cooling, the insert has end up exactly at the rotational center of the finished part. Even a thousandth of an inch off center, and the part would not meet the balance requirement.

We tackled the insert location problem in two ways: We designed the tooling to lock in the position of the tapered, knurled insert within the cavity. We also made significant design-for-manufacturability (DFM) improvements to the insert itself — everything from the insert’s tapered geometry to its dimensional tolerance and from its knurl pattern to the thickness of its coating.

The DFM work proved essential because the insert design as spelled out on the initial print would not have supported a predictable, accurate and repeatable process for making balanced parts. And the fact that we are able to precision machine the insert in our facility makes it possible to control the quality and consistency of the insert, which also contributes to the ultimate balance of the part.

Give it a spin. All of the seed spreader components we make go through a rigorous quality assurance and functional testing process. Dimensions are checked on a coordinate measuring machine. And each of the seed spreaders gets a 12,000 rpm spin custom test rig that we built to support this job. Most of the parts pass the test requirement — balance to better than 2.5 g-mm — as molded. For parts that are a little off, we developed a trueing process in which we selectively remove some of the nylon to bring the part into balance. So at the end of the day, yields for this challenging part are close to 100%.

Parts that require a multi-disciplinary manufacturing approach are not unusual for us. You can learn more about our capabilities here or you can start the quoting process now.