If you buy injection molded parts, you’ve probably considered sending your job offshore to cut costs. So you may be surprised to hear that the cost differential for domestic molders isn’t as much as you might think.

However, not just any domestic molder can close the cost gap. It’s important to choose one that has the right enabling technologies in place. These technologies will drive toward cost savings that are equal to — or better than — the cost of an offshore company.

The right domestic molder will also offer several other advantages — from simplified logistics to design-for-manufacturability support. Once you add these other variables to your cost equation, you’ll realize they tip the scale in favor of onshore production.

What to Look For in a Partner

The right injection molding operation will offer several enabling technologies that make it possible to handle high-volume production runs with a favorable onshore cost equation. These technologies include:

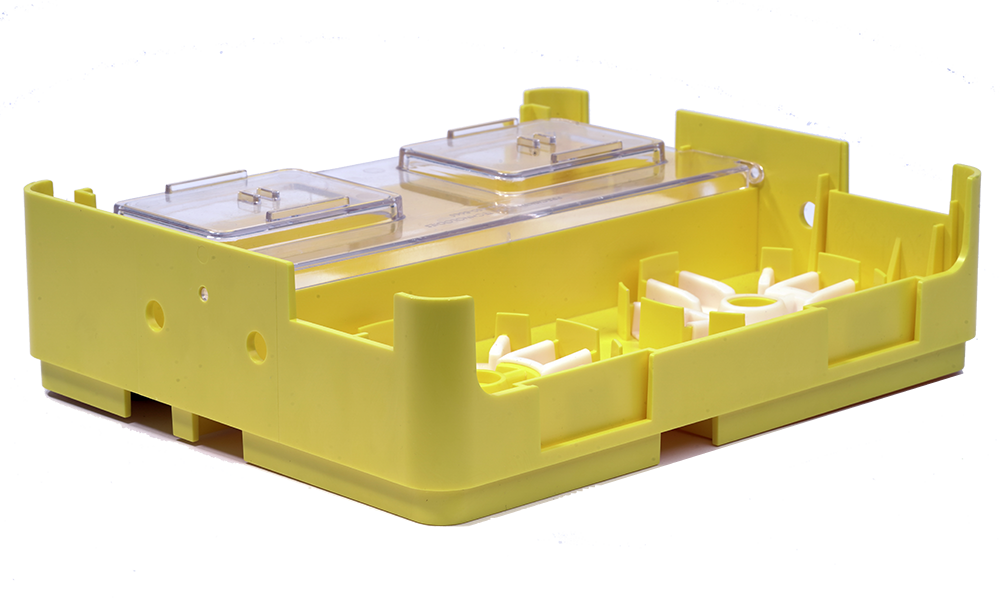

Multi-cavity mold capabilities. Working with a domestic molder that offers multi-cavity capabilities can go a long way toward stretching your manufacturing dollar. At Precision Tool Technologies, for example, we have the ability to design, produce, run and maintain high-precision multi-cavity injection molds, all while guaranteeing the highest levels of accuracy, repeatability and predictability.

Lights-out manufacturing. At the same time, our unattended, or “lights-out,” molding operation saves manufacturing and labor costs. Instead of operating one or two shifts a day with a shop full of operators, we can run high-volume jobs unattended overnight. We run only electric molding machines with integrated parts handling robots, enabling us to increase our production rates, maximize efficiency and create a true lights-out operation.

In addition to our multi-cavity and lights-out capabilities, we maintain a clean manufacturing environment with all-electric equipment, ensuring optimal conditions for high-quality plastic injection molding. Our other technical capabilities include:

- The ability to handle difficult-to-mold thermoplastics

- Cavity balancing, ensuring part-to-part consistency in multi-cavity tooling

- Insert overmolding

- Secondary operations like in-house laser marking and pad printing.

- Coordinate measurement machines (CMM), which validate as-molded quality

Reaping Additional Advantages

Beyond just the cost benefits that come with multi-cavity and lights-out manufacturing capabilities, the right domestic molder offers other advantages as well. The first is design and engineering expertise—particularly from a design-for-manufacturability (DFM) standpoint. With this support, you can be sure your caps, closures, medical disposables and other parts not only meet their functional requirements, but also mold efficiently and with minimal costs.

Other benefits include simplified logistics, less shipping expenses and minimal time spent on communication, shipping and delivery.

Getting Started

Still not convinced that domestic injection molding can save you money? Send us a request for a free quote, and we’ll prove it to you. Click here to start the quoting process.

Get Started