- +1 (800) 450-8665

- Careers

- Corporate Home

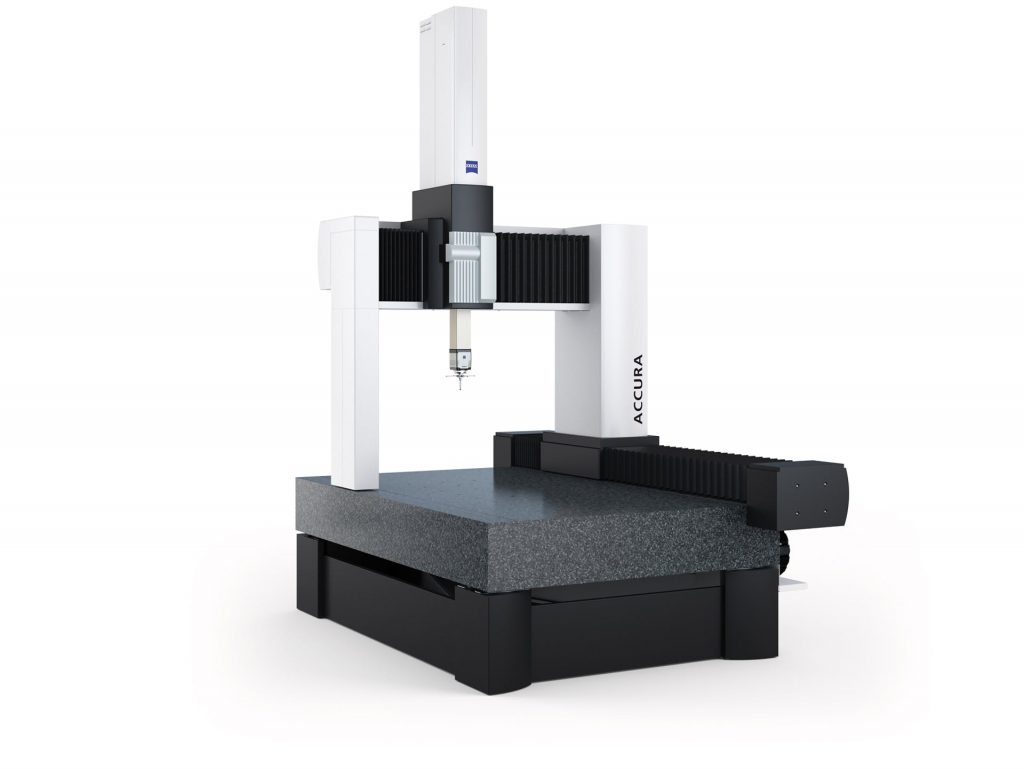

Quality is baked into everything we do—regardless of the size of the job or how quickly it needs to ship. In our ISO 9001:2015 shop, we operate a wide variety of cutting-edge metrology and inspection equipment and have invested over $1 million in our quality control systems. We’ve also built the quality control expertise and documentation processes to get the most from these systems, ensuring your parts will meet the highest quality standards.

Capabilities and Equipment

Contact us today to learn more about how our quality control capabilities can help meet your unique application requirements.